Product display

Contact Us

Tel:0086-315-5165187

Fax:0086-315-3115512

Address: Dabari Industrial Park, Yinchengpu Town, Fengrun District, Tangshan City

E-mail:qmx@tsqmx.com

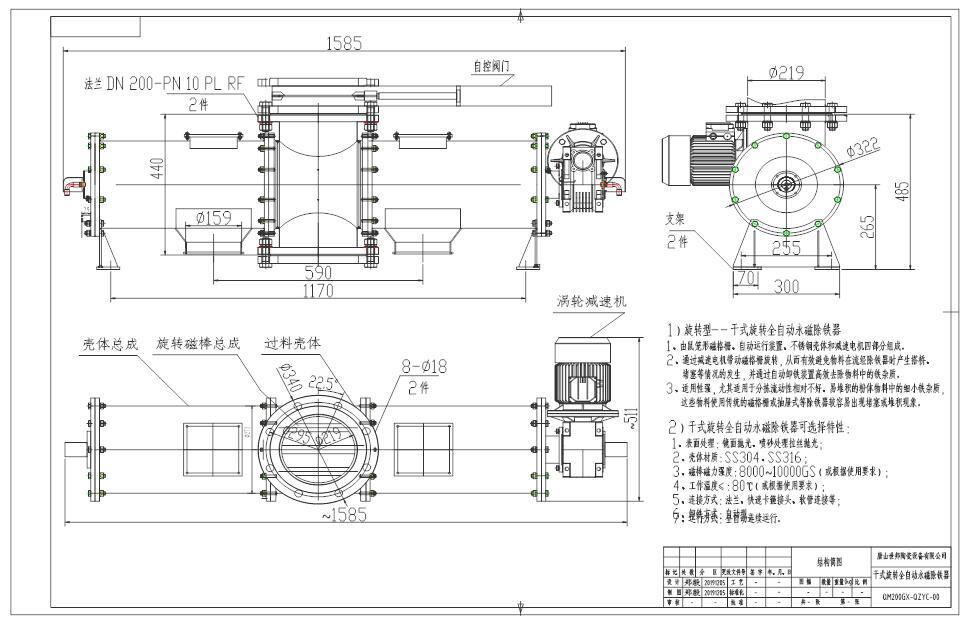

QM200GX-ZYC dry rotary full-automatic permanent magnet iron remover

Focus on the development and manufacture of high-performance electromagnetic iron removal equipment.

Key words:

QM200GX-ZYC dry rotary full-automatic permanent magnet iron remover

Product Details

Structure diagram

Main functions and configuration:

1)QM200GX-ZYC dry rotary full-automatic permanent magnet iron remover has the functions of continuous operation and automatic iron unloading, and all actions are controlled by microcomputer (PLC).

2) The frame shell is made of 304 stainless steel.

3) It is especially suitable for automatic separation of fine iron impurities in powder materials with relatively poor fluidity and easy accumulation.

4) can cycle continuous work.

5) The magnetic system is made of rare earth material magnetic block and its accessories by advanced process structure. If it is due to quality reasons, the supplier is responsible for free replacement.

6) Electronic control (Taiwan FATEK)PLC (microcomputer) (SCHNEIDER) button and relay

7) Import and export optional, flange or square interface for user convenience; or according to user requirements.

Technical parameters:

1, input voltage: AC380V

2, standard series magnetic bar sleeve table magnetic 8000 ~ 10000GS

3. The working temperature is not more than 100 ℃

4, turbine reducer RV75, matching motor 1.1kw

5. Equipped with a rotating squirrel cage magnetic grid, composed of 8 sets of Φ25 magnetic rods, the effective magnetic zone length is 260mm

6, air pressure:>0.65Mpa

On-site installation materials:

1. Input voltage: AC380V

2. Feed inlet: provide matching 'automatic control valve' and inlet connection on site.

3. The discharge port: can be configured according to user requirements and actual conditions.

4. air source pressure:>0.65Mpa, not too far from the iron remover, and the hose interface is Ø10mm gas pipe joint.

Application Scenarios of Dry Process

Application Scenarios of Dry Process

Application Scenarios of Dry Process

Application Scenarios of Dry Process

Application Scenarios of Dry Process

Application Scenarios of Dry Process

Application Scenarios of Dry Process

Application Scenarios of Dry Process

Wet Application Scenarios

Wet Application Scenarios

Wet Application Scenarios

Wet Application Scenarios

Wet Application Scenarios

Wet Application Scenarios

Wet Application Scenarios

Wet Application Scenarios

Related Products

Product inquiry

Please leave your contact information, we will provide you with new product information!